Every month is Food Safety Month in our book, but September gets the official title.

Sanitation was a top priority in our business long before the pandemic, yet material and equipment technology has continued to evolve since we all faced the germ challenge of a lifetime in spring of 2020.

Understanding what different sanitation technology and features can and can’t do can be confusing, however. If you’ve ever wondered about the capabilities and limitations of antimicrobial surfaces, UVC light disinfection, and self-cleaning equipment, read on to see what makes sense for your kitchen and what may not.

1. Antimicrobial Surfaces and Materials

Antimicrobial surfaces and materials are manufactured with permanent antimicrobial agents such as copper and silver ions that slow the reproduction and growth of harmful microorganisms. The operative word here is “slow.” Antimicrobial surfaces and materials still require regular cleaning.

From the Welbilt lines, Convotherm ovens and Kolpak walk-ins come standard with an antimicrobial handle, a big plus considering how many hardworking hands touch their handles.

Welbilt’s Delfield Shelley and EcoMark serving lines can be custom manufactured with antimicrobial laminate.

All Cambro Camshelving series—Premium, Elements, and Basics Plus—have Camguard® antimicrobial shelf plates that inhibit the growth of harmful bacteria and microbes.

Camshelving easily wipes clean or shelf plates can be removed to run through the dishwasher.

Cambro Large and Small KD Service Cart handles also have permanently molded-in Camguard antimicrobial to inhibit the growth of mold, fungus, and bacteria.

Handles easily wipe clean between uses.

MercerMax Cut Gloves by Mercer Culinary provide ANSI level A7 cut protection with built-in antimicrobial for increased sanitation.

They are also machine washable and bleach safe.

2. Ultraviolet Light

UVC lights have been used safely and effectively for decades to reduce the spread of bacteria and viruses by disinfecting air, water, and nonporous surfaces. According to the FDA, it is most effective when the bacteria or virus is directly exposed to the radiation, meaning that if anything blocks the light rays, it may not work.

Proper equipment construction and installation are also important to protect eyes and skin from direct exposure to UVC radiation, so always look for applicable product safety certifications and use an authorized installer.

The Edlund Helios UV Antimicrobial Knife Cabinet KSUV-18 uses ultraviolet light to provide a 99% reduction in E-Coli bacteria in as little as 5 minutes.

Mirrored interior surfaces and non-UV filtering slotted knife holder maximize contact between light and blades.

Filtered plexiglass door protects the operator from UV rays while allowing full view of knives inside.

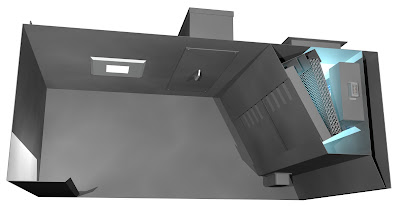

UVC light also breaks down odor and fat/grease molecules, which makes it perfect for kitchen exhaust systems. Caddy Series SHBCU Exhaust Systems use ultraviolet light technology to keep the plenum and duct virtually grease free.

This type of system is ideal for reducing odors and fire risk in heavy grease-producing applications such as hotels, hospitals, centralized cooking facilities, institutions, and restaurants.

3. Self-Cleaning Capability

Adding self-cleaning capability to commercial cooking equipment involves software, plumbing, cleaning agents, and an integrated housing to hold them. Some equipment can even programmed to alert staff when it’s time to clean.

Convotherm combi ovens with ConvoClean+ feature a fully automatic cleaning program complete with a steam disinfectant cycle.

Safe for employees since no contact is made with hot water or detergents, the operator simply selects eco, express, or regular mode for the desired level and speed of cleaning.

A final steam-disinfection and drying cycle sterilizes the cooking chamber to guarantee optimal hygiene.

4. Reusable Disposables

You read that right. It’s not an oxymoron. Although this concept may not be as high tech as ions and radiation, at the end of the day, every type of foodservice operation still requires manual cleaning of some kind. Material technology can increase product life and minimize use of natural resources all at the same time.

Blu™ Towels from Mercer Culinary are designed to be used 4 to 6 times (or shifts) before disposing.

An environmentally friendly alternative to woven cotton dish towels, these 100% biodegradable and compostable non-woven cotton towels result in less laundry and lower water, chemical, and energy consumption.

Technology continues to evolve to help foodservice operations of all sizes meet ever-changing demands as efficiently and safely as possible. Please don’t hesitate to contact us for help with your questions and operational challenges. We’re here for you!